Innovative Robotics Solutions for Large Manufacturers

- MESH Solutions

- Oct 10, 2025

- 5 min read

Updated: Oct 15, 2025

In today's fast-paced manufacturing world, staying ahead of the competition is crucial. Large manufacturers are constantly seeking ways to improve efficiency, reduce costs, and enhance product quality. One of the most promising avenues for achieving these goals is through innovative robotics solutions. These technologies are transforming the manufacturing landscape, enabling companies to streamline operations and adapt to changing market demands.

As we explore the various robotics solutions available, we will highlight specific examples and practical applications that can benefit large manufacturers. From automation in assembly lines to advanced robotics in logistics, the potential is vast.

The Rise of Robotics in Manufacturing

Robotics has come a long way since the first industrial robots were introduced in the 1960s. Today, they are more sophisticated, versatile, and accessible than ever before. Large manufacturers are increasingly adopting robotics to enhance productivity and efficiency.

Key Benefits of Robotics

Increased Efficiency: Robots can work around the clock without breaks, leading to higher output.

Improved Quality: With precise programming, robots can perform tasks with a high degree of accuracy, reducing errors.

Cost Savings: While the initial investment may be significant, the long-term savings in labor costs and increased productivity can be substantial.

Flexibility: Modern robots can be reprogrammed for different tasks, allowing manufacturers to adapt quickly to changing demands.

Safety: Robots can take on dangerous tasks, reducing the risk of workplace injuries.

These benefits make robotics an attractive option for large manufacturers looking to enhance their operations.

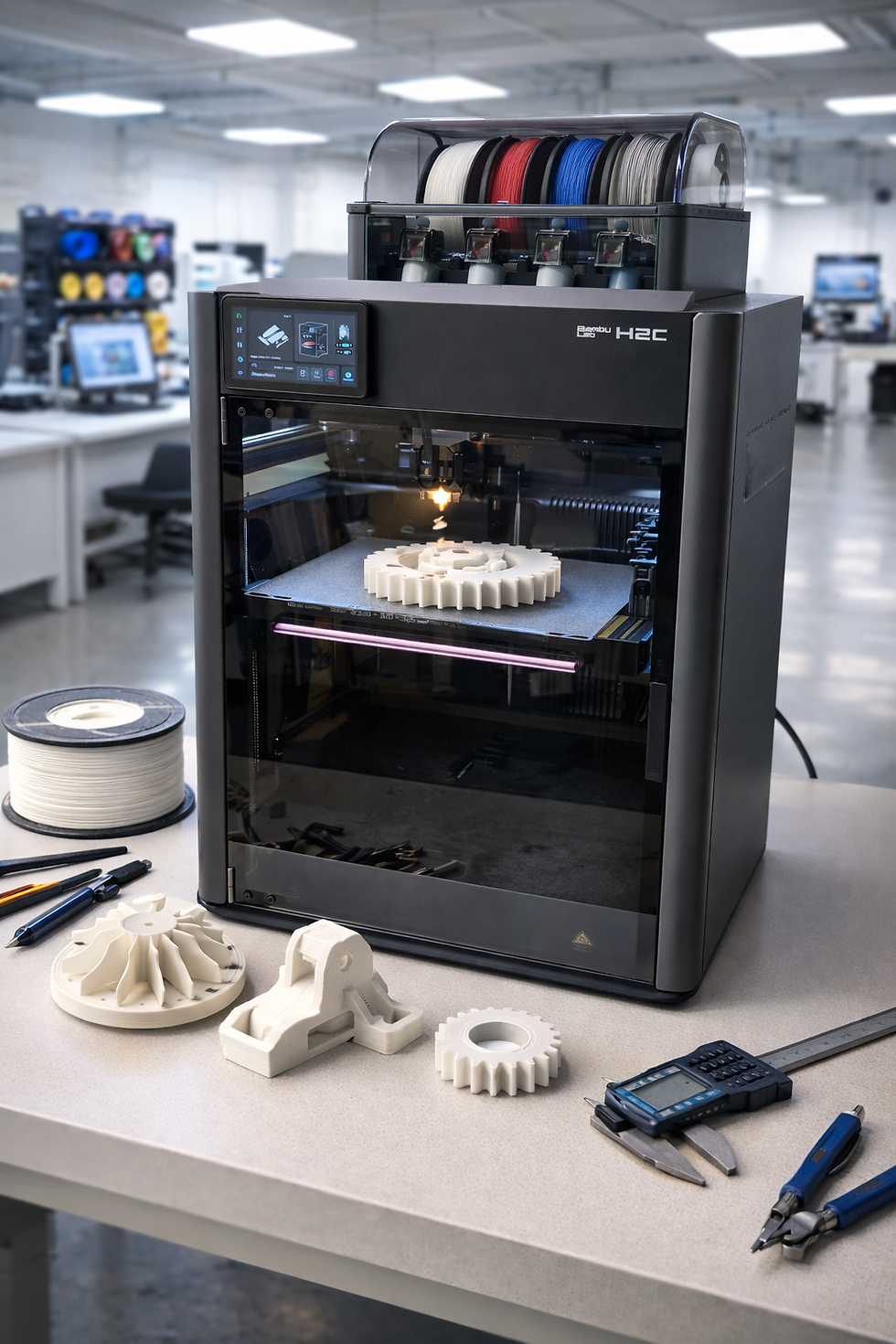

Types of Robotics Solutions

There are several types of robotics solutions that large manufacturers can implement. Each type serves a unique purpose and can be tailored to meet specific needs.

1. Industrial Robots

Industrial robots are the backbone of many manufacturing processes. They are used for tasks such as welding, painting, assembly, and packaging.

Example: A leading automotive manufacturer implemented robotic arms for assembly line tasks. This not only sped up production but also improved the quality of the final product.

2. Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside human workers. They are equipped with sensors to ensure safety and can assist with tasks that require human oversight.

Example: A large electronics manufacturer introduced cobots to help with the assembly of delicate components. This allowed human workers to focus on more complex tasks while the cobots handled repetitive actions.

3. Autonomous Mobile Robots (AMRs)

AMRs are used for material handling and logistics within manufacturing facilities. They can navigate through spaces, transport materials, and even interact with other machines.

Example: A major food processing company deployed AMRs to move ingredients from storage to production lines. This reduced the time spent on manual transport and improved overall efficiency.

4. Robotic Process Automation (RPA)

RPA involves using software robots to automate repetitive tasks in business processes. This is particularly useful in administrative functions.

Example: A large pharmaceutical company utilized RPA to manage inventory and order processing. This freed up employees to focus on more strategic tasks.

Implementing Robotics Solutions

Adopting robotics solutions requires careful planning and execution. Here are some steps large manufacturers can take to ensure a successful implementation.

Assess Current Processes

Before introducing robotics, manufacturers should evaluate their current processes. Identify areas where automation can provide the most benefit.

Set Clear Goals

Establish specific objectives for the robotics implementation. Whether it is increasing production speed, reducing costs, or improving safety, having clear goals will guide the process.

Choose the Right Technology

Select the type of robotics solution that best fits the identified needs. Consider factors such as the complexity of tasks, the environment, and budget constraints.

Train Employees

Training is essential for a smooth transition. Employees should be educated on how to work alongside robots and understand their capabilities.

Monitor and Adjust

After implementation, continuously monitor the performance of the robotics solutions. Be prepared to make adjustments as needed to optimize efficiency.

Real-World Success Stories

Several large manufacturers have successfully integrated robotics solutions into their operations. Here are a few notable examples.

Case Study: Tesla

Tesla has been at the forefront of using robotics in automotive manufacturing. The company employs a combination of industrial robots and cobots to streamline production. This has allowed Tesla to ramp up production while maintaining high-quality standards.

Case Study: Amazon

Amazon uses a fleet of robots in its warehouses to enhance logistics and order fulfillment. These robots work alongside human employees to pick, pack, and ship products efficiently. The integration of robotics has significantly reduced delivery times and improved customer satisfaction.

Case Study: Boeing

Boeing has implemented robotics in its assembly lines for aircraft manufacturing. Robots are used for tasks such as drilling and fastening, which require precision. This has not only improved efficiency but also enhanced the safety of workers.

Challenges and Considerations

While the benefits of robotics are clear, there are challenges that large manufacturers must consider.

Initial Investment

The upfront cost of robotics can be high. Manufacturers need to weigh the long-term benefits against the initial investment.

Integration with Existing Systems

Integrating robotics with existing systems can be complex. Manufacturers must ensure that new technologies work seamlessly with current processes.

Workforce Impact

The introduction of robotics may lead to concerns about job displacement. It is essential to communicate the benefits of robotics to employees and provide training for new roles.

The Future of Robotics in Manufacturing

The future of robotics in manufacturing looks promising. As technology continues to advance, we can expect even more innovative solutions to emerge.

Trends to Watch

Artificial Intelligence: The integration of AI with robotics will enhance decision-making and adaptability.

Internet of Things (IoT): IoT will enable robots to communicate with each other and with other machines, leading to more efficient operations.

Customization: Manufacturers will increasingly use robotics for customized production, allowing for greater flexibility in meeting customer demands.

Sustainability: Robotics will play a key role in sustainable manufacturing practices, helping to reduce waste and energy consumption.

Embracing the Robotics Revolution

Large manufacturers have a unique opportunity to leverage innovative robotics solutions to transform their operations. By embracing these technologies, they can enhance efficiency, improve quality, and stay competitive in a rapidly changing market.

As we move forward, it is essential for manufacturers to remain open to new ideas and technologies. The robotics revolution is here, and those who adapt will thrive in the future of manufacturing.

In this era of innovation, the potential for robotics in manufacturing is limitless. By investing in the right solutions and fostering a culture of adaptability, large manufacturers can pave the way for a more efficient and sustainable future.

Comments