Design for Manufacturability: Why 95% of Manufacturers Leave Money on the Table

- magnummetals

- Nov 18, 2025

- 3 min read

Most manufacturers don’t have a “design problem.” They have a design-for-manufacturing problem—and it quietly costs them more than almost any obvious source of waste on the shop floor.

We see it all the time. A part gets engineered to perfection on a CAD screen… but not for the reality of high-mix work, limited labor availability, or the actual machines that will touch it. The result is familiar: extra fixturing, awkward handling, long changeovers, higher scrap rates, and processes that fight the operator instead of supporting them.

This is why Design for Manufacturability (DfM) isn’t a buzzword. It’s a financial lever. And it’s one most companies don’t pull.

DfM is the difference between “runs okay” and “prints money.”

When you design a part, fixture, or process with the actual manufacturing environment in mind, a few things happen:

1. Fixtures get simpler. The best fixtures aren’t works of art—they’re boring, robust, and easy to load. Simplifying fixture design reduces machining time, avoids unnecessary detail, and keeps operators from wrestling parts into position.

2. Tooling becomes modular. Modular tooling lets a line shift from Part A to Part B without ripping the entire setup apart. It reduces downtime, increases flexibility, and lets a manufacturer respond to demand instead of tripping over their own process.

3. Changeovers shrink dramatically. We’ve seen changeovers that take 45 minutes drop to 5. Not through magic—through designing parts, nests, and workflows that make sense for automation and humans. Fast changeovers are often the difference between profitable and painful.

4. Scrap disappears where it shouldn’t exist in the first place. Most scrap isn’t caused by operators. It’s caused by design decisions made months (or years) earlier. DfM addresses the root: how parts are held, how they’re fed, how variation is handled, and how consistent the process is from cycle to cycle.

In short: DfM doesn’t just make manufacturing easier—it frees up real money that’s already sitting inside the product.

Where MESH Fits In

We do DfM...but we also build automation, robotics, and custom manufacturing systems—and DfM is baked into everything we touch. It has to be. A robot cell only performs as well as the parts, fixtures, and process you feed it.

Here’s how we integrate DfM into every project:

• Early Process Mapping Before we quote anything, we break the product down into how it can be presented, gripped, fixtured, and processed. This prevents downstream surprises.

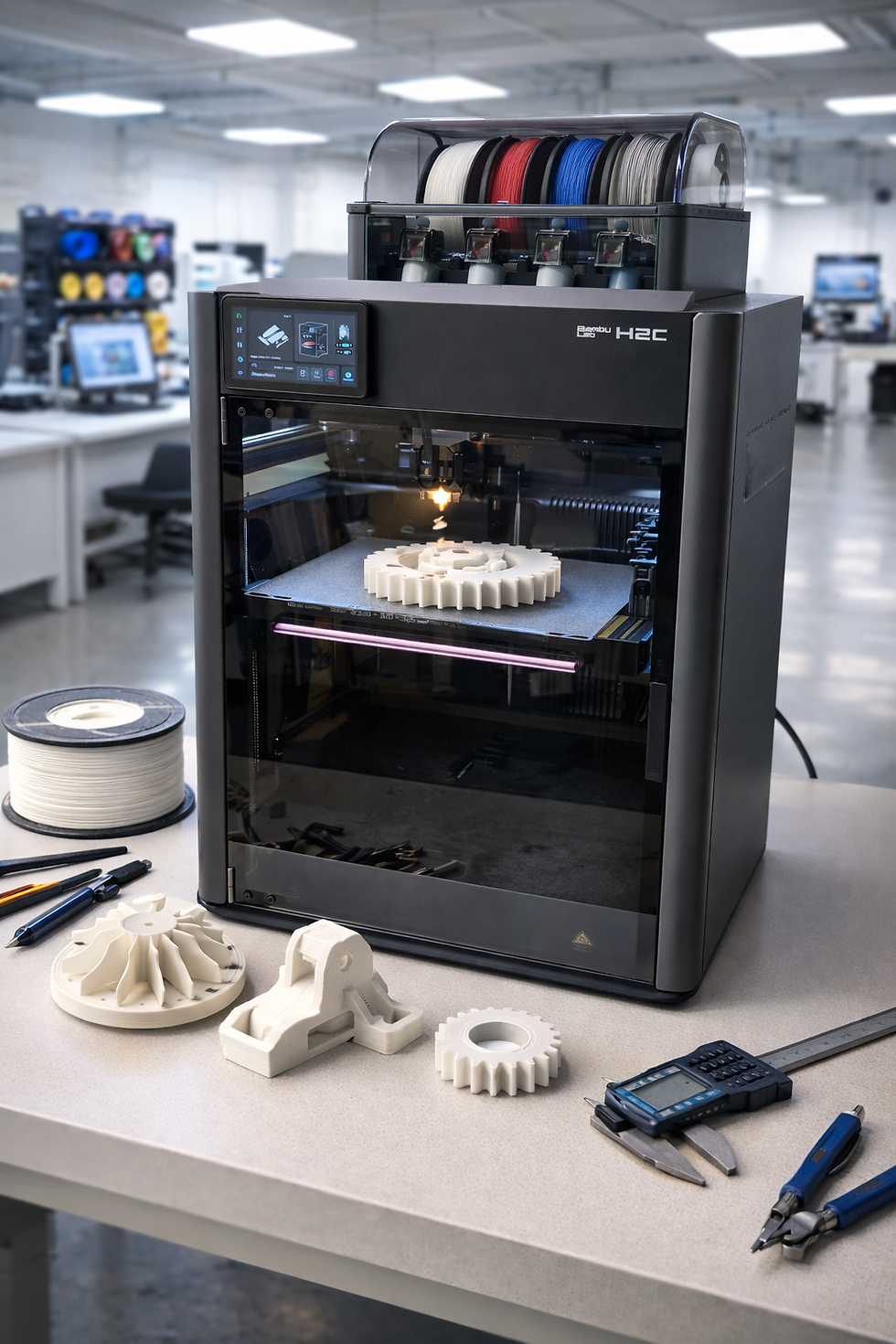

• Rapid Prototyping & Fixture Proving We design and test fixtures early—sometimes within days—so we can evaluate how they behave under realistic conditions. If something is awkward, slow, or fragile, we fix it before the build ever starts.

• Modular Tooling Standards Most cells we build include modular nests, quick-change end-of-arm tooling, and flexible fixtures that support future part variants without large capital reinvestment.

• Changeover Optimization We design stations and tooling so operators (or robots) can switch from one part to another quickly. Less downtime. Better flow. Higher effective capacity.

• Data-Driven Scrap Reduction We use sensors, smart feedback loops, and process discipline to eliminate variation that creeps in when designs aren’t robust. Better design → fewer mistakes → cleaner output.

Why It Matters Now More Than Ever

Labor shortages aren’t easing. Material costs aren’t dropping. Customers still expect fast turnaround, tight tolerances, and competitive pricing.

The manufacturers who win today are the ones who design smarter—not just build faster.

DfM is how you get there. It’s the quiet superpower that turns complicated into controlled, fragile into scalable, and expensive into profitable.

And it’s at the core of how MESH approaches every project we put our name on.

Comments